Surfing is a popular sport that requires the use of high-quality equipment to ensure the safety and performance of the surfer. Leashes are an essential component of the surfer’s equipment, and their quality plays a vital role in the surfer’s experience. Here are some steps to control the quality during the leash production for surfing sports:

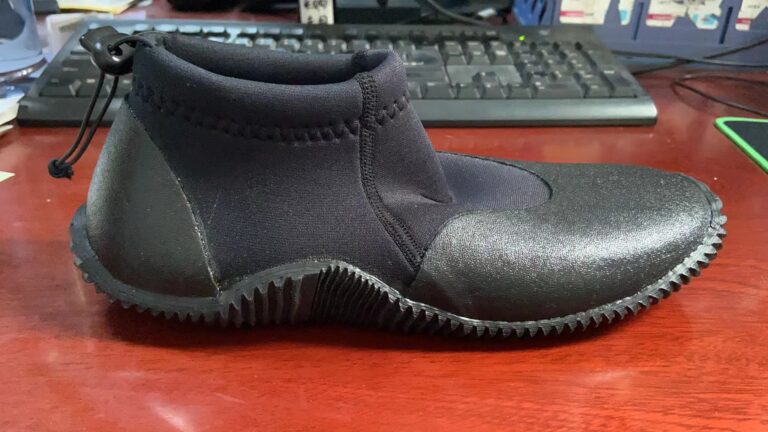

Quality Control of Raw Materials

The first step in controlling the quality of the leashes is to ensure that the raw materials used in their production meet the required standards. The raw materials used to make leashes are usually nylon, polyurethane, or neoprene. These materials should be of good quality, and their specifications should be consistent throughout the production process.

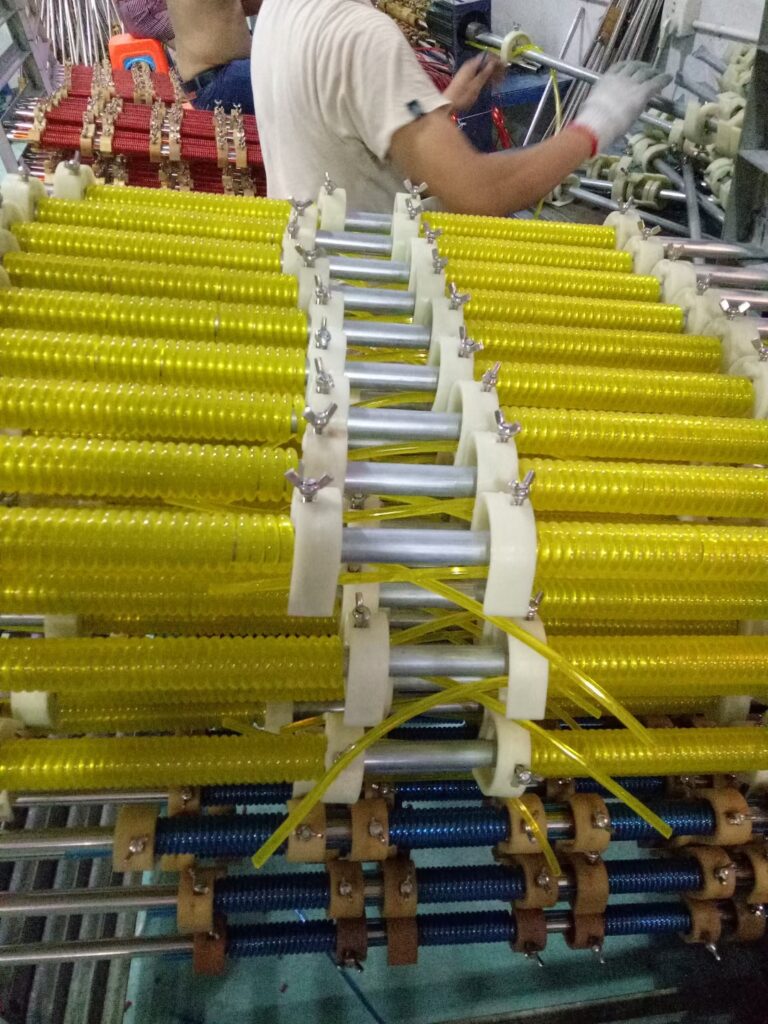

nspection of the Manufacturing Process: During the manufacturing process, it is essential to inspect each step of the production process to ensure that the quality standards are being met. The inspection should start from the cutting of the materials to the final assembly of the leashes. Any deviations from the quality standards should be identified and corrected promptly.

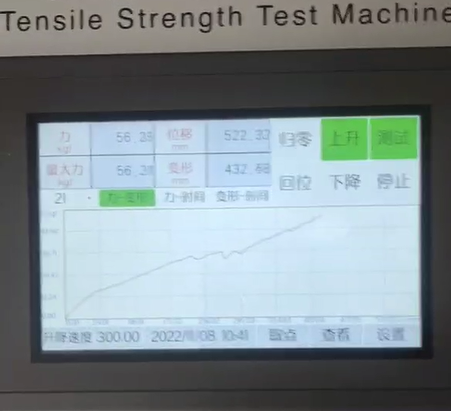

Testing the Finished Product: Once the leashes have been produced, they should be tested to ensure that they meet the required standards. The testing should include checks for the strength and durability of the leashes, as well as their resistance to the elements.

Quality Assurance

Quality assurance is an ongoing process that involves monitoring the production process and making any necessary adjustments to ensure that the quality standards are being met consistently. This may involve regular inspections, audits, and testing of the finished product.

Continuous Improvement

it is essential to have a culture of continuous improvement in the production process. This involves analyzing the production process, identifying areas for improvement, and implementing changes to improve the quality of the leashes.